Simple Shear through ECAE leads to Powerful Results

|

At SFI, we specialize in improving material performance using severe plastic deformation. Our tooling designs and materials expertise allow us to push the boundaries of bulk material properties. We are also a full-service engineering firm, offering mechanical and materials design and analysis consulting services from our staff scientists and two licensed Professional Engineers. |

Case Studies

While many of our projects are proprietary in nature, others serve as an example of what our expertise in deformation processing can do for the manufacturability and performance of a wide range of products.

Breaking Barriers

|

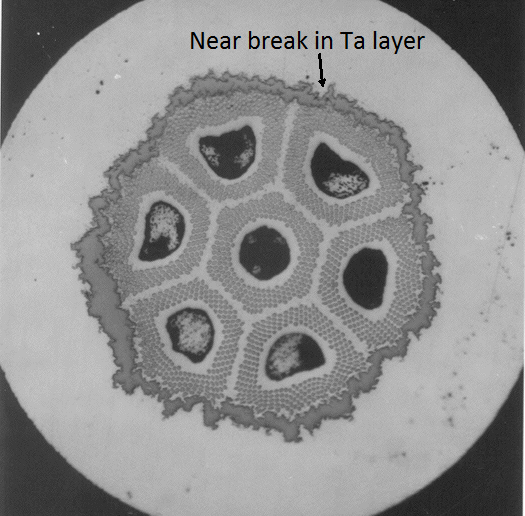

The Problem

The current density of Nb3Sn superconductors is critical to device performance in many high-magnetic-field applications such as NMR. Pictured here is a 9mm diameter wire that began as a thick-walled Cu tube with a stack of Nb and Sn bars arranged on the interior before being extruded and drawn down. Separating the internal and external components is a Ta sheet preventing Sn contamination of the Cu when the strand is heated to react the Nb and Sn. A break in this barrier can destroy the properties of a conductor and reduce painstakingly created and costly strand to scrap. Given the need to improve current density, the Ta layer should be as thin as possible. However, manufacturing yield requires thick Ta to limit the risk of breaks. A dramatic improvement to Ta barrier co-deformation during conductor drawing would allow for thinner Ta sheet, a lower rejection rate, and, in the end, higher magnetic fields. |

|

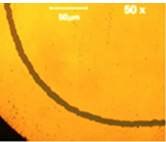

The SFI Solution

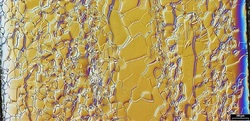

Following a thorough study, we developed a thermomechanical processing strategy that consistently produced Ta sheet with uniform microstructure and preferred texture. SFI produced Cu-Ta monofilament wire to demonstrate the enhanced co-deformation of our processed tantalum sheet, as shown in the included image. |

Creating Clones

|

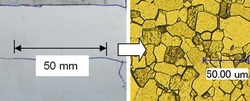

The Problem

In applications where repeatable surface finish and accurate geometry is key to product performance, starting material can make a huge impact on scrap rate and the bottom line. Non-uniform microstructure and texture can lead to variable dimensions and surface characteristics in formed components. Nb sheet (and other forms) often suffer from wide variations in grain size that persist through further forming operations and confound tolerances. This variability can be traced back to castings with exceptionally large grains. |

|

The SFI Solution

Using SPD and two steps of recrystallization, SFI developed a process that consistently produced Nb with a uniform, fine microstructure despite wide variations in the starting material. We are currently investigating the impact this process will have on economical production of high performance RF cavities and other applications. |